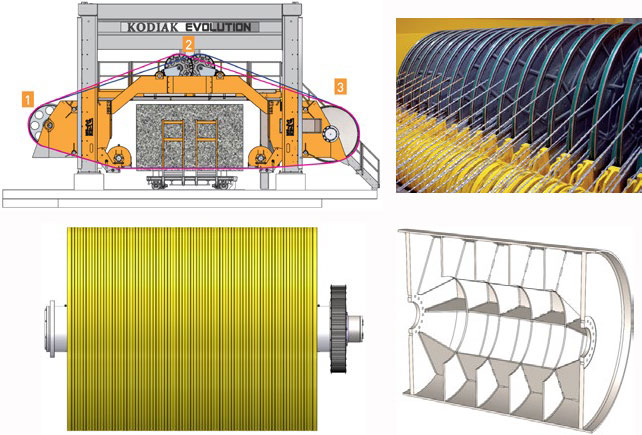

As there is a growing trend for diamond wire cutting technologies in the world, diamond wire technology producers present their latest technology products to the sector. BM, as one of the leading technology producer companies in natural stone sector launched new high technology equipped KODIAK EVOLUTION.

Main innovations of evolution:

BM introduced the new KODIAK EVOLUTION model as follows: “The new KODIAK EVOLUTION BM is the sum of the best technical innovations and solutions in order to minimize the costs of sawing and maintenance.” The renewed KODIAK EVOLUTION has extra features that will reduce production, maintenance and working expenses in the production process.

Reduction of the costs: Maintenance and working

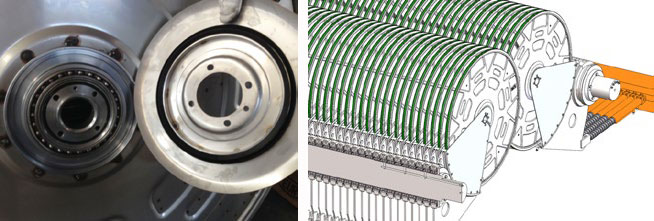

Characteristics of bearing installed on tensioning wheels d.1000 mm: BM installs standard international bearings easy to be found all around the world for a cheap price. The low buying price reduces the cost of the work. Other machines multi-wires install very expensive and exclusive bearings, so the customer is forced to buy only these special items at the price decided by the supplier and not by the world concurrence.

Easy change of the diamond wires:

BM KODIAK EVOLUTION can save diamond wires in stock in order to change quickly a damaged one.

Easy change of the bearing of the 1000 mm wheels:

KODIAK EVOLUTION machine allows removing one or all-tensioning wheels, changing every single bearing in less than 2 hours.

The motorized block trolleys:

TECNICAL DATA: – Dimensions: mm 3000 x 2300. – N.2 motors: kw. 1,5. – Capacity max: tons 60.

Life of the diamond wire:

Each wire suffers the flexing action only on 3 points, without any dangerous grade. So the cost of the cut per each square meter are reduced. The result is the best working condition for the wire, which upgrade its performance and life.

Bigger diameters:

- Reduction of the inclination angle of the diamond wire = increase life of the wire

- Reduction of cycles per minute = longer life of the bearings

- Bigger contact surface of the wire on the rubber profile = less consumption of rubber profile

The Patented Tensioning System: for the homogeneous tensioning of each diamond wire by hydraulic lever system THE WHEELS OF DIAM. 1000 mm FOR TENSIONER. Made up in stainless steel, and installed on special bearings.

The Driving Drum Of 2 Meters:

SPECIAL DRIVE DRUM OF DIAMETER 2000 mm..

Configuration of the machine:

The KODIAK EVOLUTION can be set with 3 measures of diamond wires: 7,3 mm diameter – pitch 9,7 mm 6,3 mm diameter – pitch 9,3 mm 5,3 mm diameter – pitch 9,0 mm The pitch of the cannels of the guiding drums changes according to the diameter of the wires: 7,3 mm diameter – pitch 9,7 mm

N.1 Main Control Panel With Touch Screen:

The control system is very easy it is also customizable with lan connection to the office. The machine is complete with central control unit, with electric equipment, and other automatic safety and control devices. A SPECIAL APP bade by BM, allows the user to control and monitor the machine, from any tablet or smartphone Android, Windows and Apple.

+90 532 585 51 95

+90 532 585 51 95 +90 532 585 51 95

+90 532 585 51 95