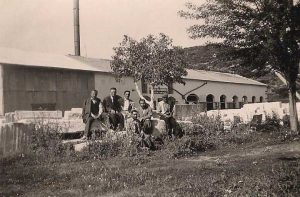

The historical marble factory in Saraylar Town of Marmara Island, which is one of the most ancient marble quarries of the world, is about to Fall into pieces..

The ancient marble factory in Saraylar Town of Marmara Island, which was established at the beginning of the 1900’s, is wearing down day by day. This historical structure cannot be restored as it belongs to a Foundation.

Marmara Marble is mined from the Saraylar Town of Marmara Island, which is known to be the oldest marble production site of the world with more than 3 thousand years old marble quarries. This is almost the first industrial factory in Marmara Island and in Turkey. In the Island, where electricity is not available, there were marble processing machines, which used to run by the steam energy generated from burning coal. The factory was handed over to a foundation, which was also founded by the owners of the factory. This structure and the machines inside it are still waiting for a miracle to regeneratethem!

Establishment Process of the Mermer Taş Factory!

Mehmet Efendi, owner of a marble processing atelier in İstanbul, Unkapanı, ship owner Hakkı Bey of Paşabahçe and another person from Manizade came together to establish the first marble processing factory in Saraylar Island in 1912. In spite of the 3000 years of marble production history of the Island, there was not a single processing factory until that time.

It Was in Use Until 1974!

The factory called Mermer Taş, was founded in 1912. The factory, which is a co-production of the Italian and the Belgian, was working with the steam energy obtained from burning coal because there was no electricity in the Island. Its production continued without any interruption until 1974. However, after then, the owners of the factory decided to stop production and abandoned the factory idle. The factory building was built by the British and the 8 advanced engineering product, steam powered gang saws were made by the Belgians. As result of the disputes among the partners in 1930, the factory was bought by Salih Sabri Karagözoğlu, who was also working in marble sector. Salih Sabri Karagözoğlu has made big investments to increase the capacity of the plant and ordered new steam powered gang saws from a Belgian company.

Mermer Taş Factory contributed to the foundation of Young Turkish Republic!

During the years when Salih Sabri Karagözoğlu bought the factory, the Republic of Turkey was in the restructuring period. Many official buildings, Ministry buildings, Stations, Schools, and Justice Palaces were being built especially in Ankara and their marbles were exported from Italy. The only marble production factory in Turkey at that time was the Mermer Taş factory, which was not efficient to meet the needs of such state projects, since it could not work at full capacity. Salih Sabri Karagözoğlu increased the capacity of Mermer Taş seriously with the additional investments he made. Following the completion of the investments, Salih Sabri Bey went to see Atatürk and requested to undertake all marble installation works of the public buildings. After that, by order of Atatürk, all marble imports from abroad were cancelled and Mermer Taş was contracted to provide marble to all State projects. Thus, the factory, which used to process Marmara Marble only until that time, began to process different color, exported marble blocks in the Island.

What was the working system of Mermer Taş?

Seven gang saws run by another steam-powered gang saw in a marble factory in an island with no electricity. We listened to the story of Mermer Taş factory from Muhittin Uygun, who spent his childhood and youth here:

“My father was the night watch of Mermer Taş Factory. We were staying in one of the subterranean houses, where this factory was located. There were three houses on the right side of the entrance. Tahir Öztaş, who was the production director of the factory, owned one of these houses. Ahmet Efendi, the father of Tahir Öztaş, was the person who served as the production manager in the first years of the establishment of Mermer Taş. After Ahmet Efendi passed away, this duty was given to Tahir Öztaş. There was a system in the factory that was even superior than the modern gang saws that are still in use today. A main flywheel and a shaft to which the pipes coming from the chamber, where the coal-burning giant furnace was rotated by steam energy, and the other 7 coils connected with these flywheel belts were starting to rotate. The gang saw in use was connected to the system and the gang saw, which accomplishes its cutting mission, was removed from the belt system. There were boxes filled with special silica sand to cut marble faster on all gang saws. Workers were shaking these boxes and spreading the sand over the blocks in a balanced manner. At the same time, the water was flowing along with the silica sand.

With this system, Marmara marble could only be cut up to one cm in an hour. Silica sand, which was used as an abrasive in cutting marble and coal to obtain steam, was brought to the port of the Island by wooden ships of that time, once a week. Sometimes different colors of marble blocks from different areas were being transported to the island with the same method. The blocks were being lifted from the ships with the help of a crane moving on the rail of its own port and being carrid to the required areas by manpower. The blocks produced in the island were being transported by the own trucks of the factory. One of those trucks is the 1946 Ford, which is still parked in front of the factory. The other truck was carrying blocks between the Badalan quarries and the factory. Both of the trucks were running with gasoline. The plates obtained from the blocks in the factory were sent to all parts of Turkey, mainly Ankara, Istanbul and Izmir. ”

We were still confused with the question; “How could a single gang saw run those 7 other gang saws?” We asked Muhittin Bey to tell us its working mechanism in detail. He explained as follows: “The main machine of this factory was working with steam. The first movement was being transferred from the main machine to the main shaft. After that, the cutting machines were moving to the gang saws. There were seven gang saws on one side and one gang saw on the other side connected to the steam room. So, there were actually 8 gang saws, but only one of them is the main gang saw that moves the other seven! All running machines, water pumps, steam pumps were working through the belts on this system. Let us explain the way the gang saws work: The first gang saw works by means of a flywheel after the block is put into the machine and the saws go down. When the machine finishes working, the system switches with the belt and locks on to an other empty hoop. Then the block cutting machine stops but the system keeps running all the time. The system is not turned off when the machine stops. The water still runs on the belt, by means of the hydraulic pump system. With this system, water is poured into the sand boilers. The water circulates and pours on the blocks together with the sand placed in the grooves of the gang saws. During this process, an officer shakes the boxes so that the sand does not always flow to the same spot. He spreads them over the blocks.

The sand passes through the sifters; there are no socket, no diamonds … The sand between the slab and the metal plate work like diamond. Blocks continue to be cut by sands. With this machine, a single block was being cut in five full days. In the operation of the system, there is water going over all the machines through channels. The water gets the sand from there through the revolving engine and when each block needs to be released individually, it stops by the help of straps. There was no switch to turn off either. So how does it collect the sand? There are pumps in its bottom. The pump circulates through the belt and pumps the water into the sand boiler. The second pump transfers the water into the machines. These machines were gradually established in 1912 and beyond. Those who lived in the Island in 1912 had never even seen a car in their lives. There was not even a radio in the island but there was an advanced technology that works like this at that time!.. ”

A Small and Functional Port!

We asked the people of the island: “There were not any modern opportunities except for the human power at that time. How could those huge marble blocks were brought to the factory only by manpower and carried back to the port after they are cut? What kind of a system did you use at that period? Here is the answer: “Blocks were put on a four-wheel trailer and transferred to the factory. They were being carried back to the port with the same trailer after they are cut and processed into slabs.

Under the conditions of the day, the slabs were being carried by manpower and debarked to the storeroom of the ship. This hassle continues until the ship is full. Moreover, marble was not the only load on board. The ships were loaded with coal and silica sand. They would have to be debarked from the ship to the port and carried to the depot of the factory by manpower as well.”

The Old Factory should be transformed into a Museum!

Although some people say that there is a similar factory in Italy, I don’t believe there is any factory like this one in the world. The steam boilers and the chimney had been decayed over the time. The factory was far from being industrially economical any more after the arrival of electric power to the Island. For these reasons, the system was shut down and the plant has been quiet for years. The land in which the plant that was transformed into a foundation in the ownership of the Tahtrevan Farm in Saraylar Town was later turned by a wire mesh and closed to the interventions coming from the outside. When looking from outside, the factory seems highly ruined and as you get inside of it you see the gang saws which used to process blocks into slabs and the whole processing system abandoned to their fate. It could have been possible to make this system work again after a detailed revision. However, this did not happen. The machine tools on the counter seem like they are waiting for a sensitive hand that will turn them back to work.

Some of the lodgings of the workers were collapsed and the building at the end of the dining hall, which was being used as a mosque was completely collapsed like the dining hall itself. The minaret with the star and crescent on it was partly destroyed. The crane was covered with thorns and bushes and the 1946 model gasoline Ford van got rotten away. The small cemetery belonging to the factory workers, the boathouse with two boats, the depot where the dynamites were kept, the pier and the dock and the stockyard where the slabs were kept are waiting for their saviors. This factory, which is unequaled in Turkey and perhaps in the world, had been specially designed in accordance with Marmara Island conditions. Marmara Island and the citizens of Saraylar in the first place, Turkish natural stone sector has been struggling for the renovation and reactivation of this old factory.

Compilation by Ersin BOZKURT – Photos by Şehriban ÇİMEN

+90 532 585 51 95

+90 532 585 51 95 +90 532 585 51 95

+90 532 585 51 95